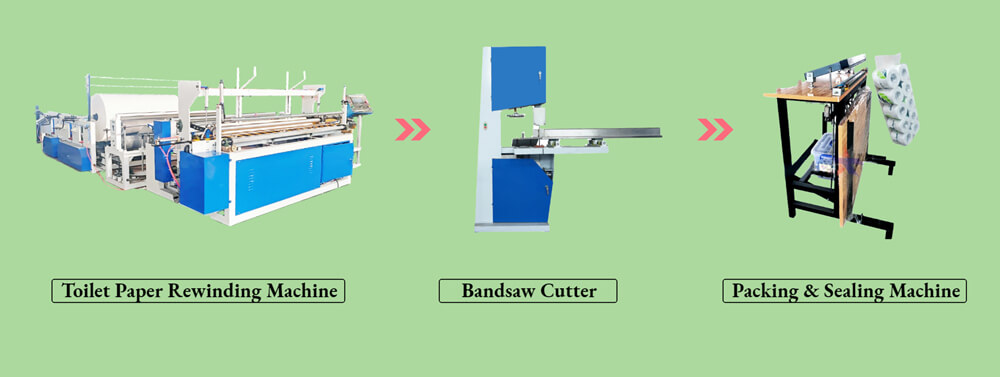

The toilet paper machine is used to produce small toilet tissue paper rolls from jumbo roll paper. The complete toilet paper production line mainly inlcudes three machines: jumbo roll toilet paper rewinding machine, bandsaw cutter and packing machine. This semi automatic type toilet paper production line has the advantage of low investment and easy operataion. It is an ideal choice for beginners. Except the 1800mm model, we also supply other models of toilet paper machine, like 1200mm, 1575mm, 2200mm, 2800mm etc.

This toilet paper rewinding machine can rewind jumbo toilet paper roll into various small diameters without changing its width. This rewinding machine has perforating unit, embossing unit and 1-3 jumbo roll unwinding stands, electricity control, glue tank and air compressor. The output paper roll is ready for cutter. The embossing roller patterns can be choosen or designed by customers.

Band-saw Paper cutting machine can cut tissue roll(which is rewinded into desired diameter) into different length. Which is an important paper process machine.

This packing machine is small and very easy to operate. The numbers of toilet paper rolls in one bag decided by customers.

We supply our customers all the necessary machines and free wearable spare parts. Raw material like jumbo toilet tissue paper rolls and paper cores can be delivered together with their machines.

If you need more information of this toilet paper production line, please contact us or send us inquiry! You will be replied within 24 hours.

Whatsapp/Mobile: 0086-13937183852

Email: andy@xingtumachine.com

| Machine Model | 1092 | 1575 | 2000 | 2200 | 2400 | 2600 | 2800 |

| Width of material jumbo roll (mm) | 1200 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 |

| Finished Products Diameter | Φ80~120mm (Tightness can be adjustable) | ||||||

| Finished Products Inner core Diameter | Φ32~60 mm | ||||||

| Material Jumbo roll diameter (mm) | Φ1200 (Other sizes please point out) | ||||||

| Jumbo Roll Inner core Diameter | Φ76.2 mm(other sizes please point out) | ||||||

| Perforation distance (mm) | 4 blade,90~160mm; 2 blade,180~320mm; | ||||||

| Production speed | 160-200 m/minute | ||||||

| Operation System | Touching-screen Multi-menu Man-machine Interface Operation System | ||||||

| Controller | PLC program | ||||||

| Mechanical driving | Driven by stepless regulator to guarantee the precise length of final products. | ||||||

| Air compressed system | 3HP air compressor, minimum pressure: 0.5Mpa | ||||||

| Power | 4kw-10kw (380V 50Hz) | ||||||

| optional items | |||||||

| Embossment | Single embossment, Double embossment, Edge embossment | ||||||

| Embossing system | 3 options: Paper roller to steel roller, rubber roller to steel roller, steel roller to steel roller | ||||||

| Jumbo roll stander | 1-3 plies | ||||||

| Rewinding unit | Core or coreless | ||||||

| Other special request for machine is welcome | |||||||